|

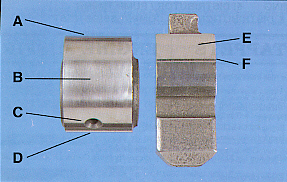

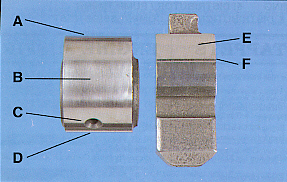

CAMSHAFT KIT FAULT

FINDING

|

|

| |

NORMAL APPEARANCE. |

|

|

FEATURES |

|

1) Components Clean !

2) Running Surfaces Will Develop A Polished Surface.

3) Note "Dwell" Mark Groove Which Develops As A Standard Feature On Most Finger & Rocker Arm Followers.

This Is The Point Off Maximum Cam Lift & Loading & Is Not A Wear" Problem!. |

| TERMINOLOGY |

|

A = CAMSHAFT NOSE

B = RAMP

C = OIL FEED HOLE

D = BASE CIRCLE

E = FOLLOWER FACE

F = DWELL MARK |

| |

|

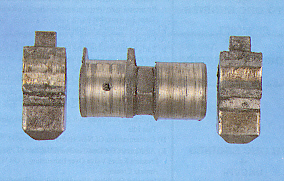

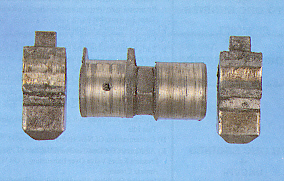

| DIRTY OPERATING CONDITIONS |

|

| FEATURES |

|

|

1) Components Layered With Filthy Carbonised Oil Crust.

2) Severe Wear & Metal Loss With Aggravated Scoring.

3) Note Oil Hole On L/H Cam Lobe Is Blocked. |

| CAUSES |

|

1) Dirt & Fuel Contaminated Oil. Latent Heat Of Engine On

Close Down Bakes The Dirty Oil & Forms An Ever Thickening Carbonised Crust. Oil Ways Block & Hydraulic

Columns Seize.

2) Resulting Lubrication Failure. |

| REMEDY |

|

| 1) Engine Requires Thorough Cleaning Which Might Involve Total

Strip Down. Ensure Fuel Emissions Are Within MOT Requirements. Use Top Quality Lubricant. |

| |

|

|

| |

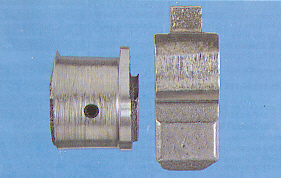

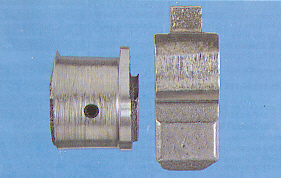

LUBRICATION CLEAN BUT INEFFICIENT. |

|

|

FEATURES |

|

1) Components Clean.

2) Severe Cam Wear & Metal Loss Extending To Base Circle.

3) Severe Follower Face Wear Over Total Contact Area. |

| CAUSES |

|

1) Pure Lack Of Oil Pressure/Supply.

2) Thin Oil Due To Fuel Contamination.

3) Old Hydraulic Ball Studs Overloading Due To Inherent Contamination. |

| REMEDY |

|

1) Check Oil Pressure & Supply If Possible At Cylinder Head

Oil Gallery.

2) Ensure Fuel Emissions Are Within MOT Requirements.

3) Renew Hydraulic Ball Studs. |

| |

|

| THE ABOVE PHOTOGRAPHS DISPLAY COMMON CAMSHAFT KIT FAILURES

ASSOCIATED WITH UNPROFESSIONAL FITTING OR INHERENT ENGINE PROBLEMS. CAMSHAFT KITS RETURNED UNDER WARRANTY DISPLAYING

THESE FEATURES WILL BE REJECTED AS NOT BEING OF FAULTY MANUFACTURE. |

|