|

|

TIMING BELT - FAULT

FINDING

|

|

|

|

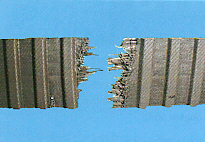

| BELT BREAK (STRAIGHT) |

|

| |

| FEATURES: |

|

|

| Belt break at 90° to belt length. |

| CAUSES: |

|

|

A) Handling crimp prior to use.

B) Use of lever to fit.

C) Too high tension. |

|

| GENERAL: |

|

A) As a rule the belt may appear perfectly serviceable other

than the failure point. If the belt is pinched during handling then the fibreglass cords can fracture resulting

in a tensile weak point.

B) Similarly the use of leverage i.e. screwdriver to lead the belt onto its pulleys will initiate cord breakage

albeit on the edge. This fatigue point will quickly run across the belt and ultimate failure will occur.

C) Too high tension is normally partnered by noisy, "whining" operation. As the engine expands the tension

increases to the point of overload and a direct clean break will occur. Tooth valley/land damage might also be

evident. |

| ACTION: |

|

| DO NOT crimp or bend belts through a radius less than that of the crankshaft pulley. Do not turn belts inside

out. Ensure tension is to OEM specification on a cold engine and repeat during belt "settle-in"

period. |

| |

|

|

|

|

|

|

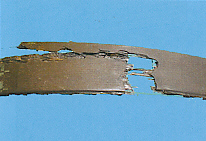

| BELT BREAK (ANGULAR) |

|

| |

| FEATURES: |

|

|

| Belt break at an acute angle with jagged tear edges. |

| CAUSES: |

|

|

A) Pulley edge climb.

B) Snatch tension. |

|

| GENERAL: |

|

A) Normally a belt which has tried to climb a pulley flange will

also show tooth edge wear. As the belt tries to ride up the pulley an over-tension situation is created. The initial

break point is due to cord fracture at peak climb.

B) A snatch tension can be caused by intrusion of a foreign object into the belt drive. Tooth and valley bruising

can also be witnessed at point of intrusion. |

| ACTION: |

|

| Ensure belt runs clear of pulley flanges and that belt guards

are fitted and are effective in protecting the belt train. |

| |

|

|

|

|

|