|

|

TIMING BELT - FAULT

FINDING

|

|

|

|

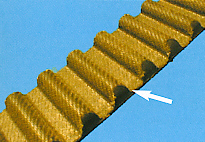

| EDGE WEAR (SMOOTH) |

|

| |

| FEATURES: |

|

|

| Belt teeth radiused inwards with polished appearance. |

| CAUSES: |

|

|

| Belt running off centre. Misaligned pulleys. |

|

| GENERAL: |

|

| Belt teeth exhibiting polished inward radiused wear on one edge

only, due to the belt just touching the drive pulley's flange. Wear is minor and will not necessarily result in

failure. However in some cases further belt edge climb could occur and damage as viewed in the next photo would

lead to ultimate belt snatch break. |

| ACTION: |

|

| Ensure new belt runs clear of pulley flanges. Re-align

as necessary. Address any excessive crankshaft end float. |

| |

|

|

|

|

|

|

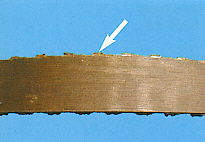

| EDGE WEAR (JAGGED) |

|

| |

| FEATURES: |

|

|

| Jagged edge wear with frayed fibrous appearance. |

| CAUSES: |

|

|

| Pulley flange climb. |

|

| GENERAL: |

|

| Belt edge contacts the pulley flange and induces a climbing action

which effectively pulls the belt further in. Depending on roughness of pulley flange chafing will develop and a

jagged/fibrous edge results. Obvious belt weakness will lead to ultimate failure. |

| ACTION: |

|

| Ensure new belt runs clear of pulley flanges. Re-align as necessary.

Address any excessive crankshaft end float. |

| |

|

|

|

|

|